FlexSim

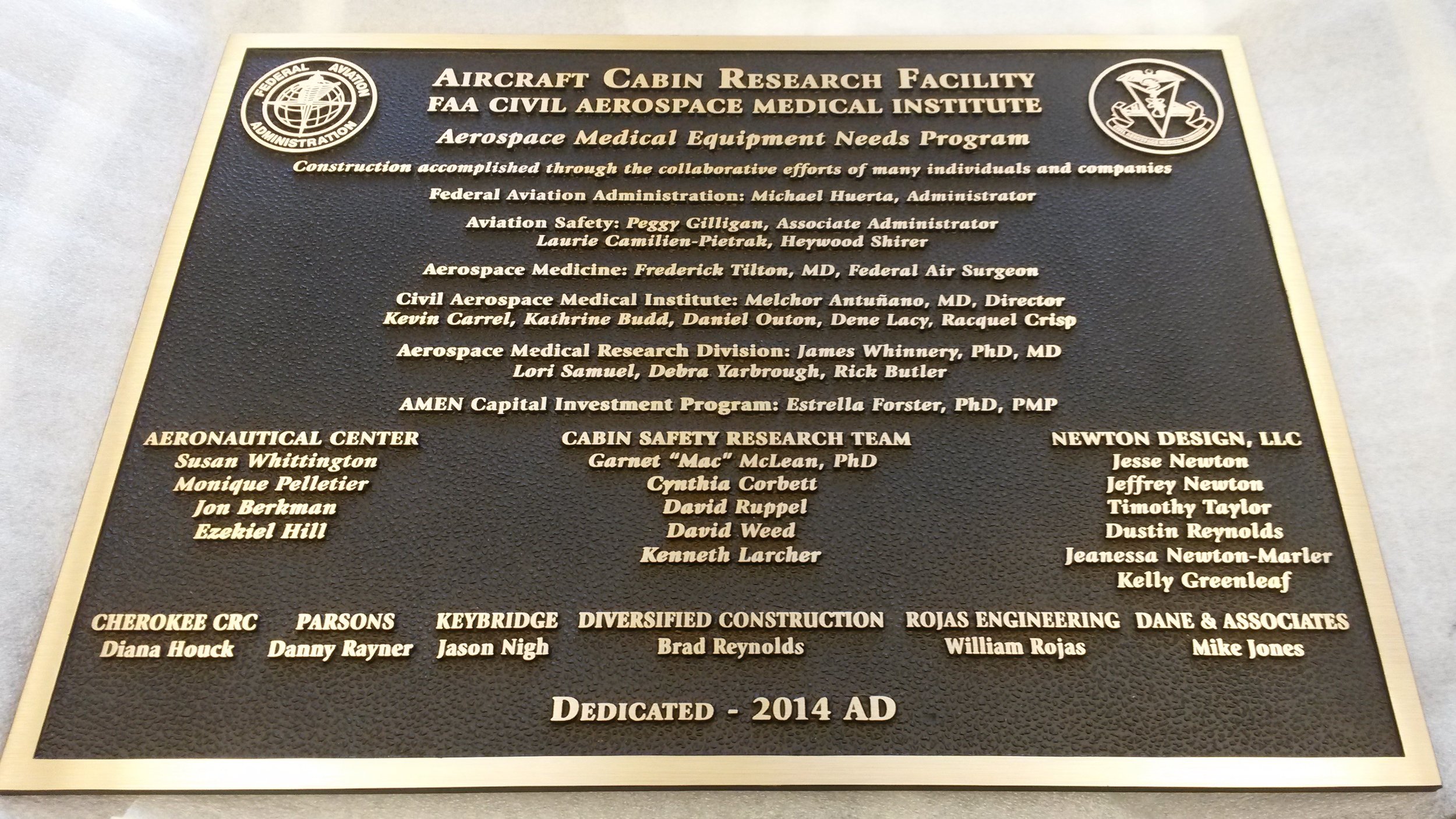

Newton Design is honored to have been selected by the Federal Aviation Administration (FAA) to develop the FlexSim, a one-of-a-kind cabin safety research simulator that is very similar to a CEET, except for the mission. The FAA Civil Aerospace Medical Institute (CAMI) is constantly researching aircraft cabin safety in an effort to improve designs, procedures, and to increase occupant safety. To assist the CAMI team in their mission, Newton Design developed this unique cabin simulator. The FlexSim is capable of simulating multiple fuselage widths and cabin configurations, providing the FAA with remarkable mission flexibility in one simulator. The FlexSim is mounted on a custom designed and manufactured positioning system, allowing the CAMI team to study the effect of abnormal landing conditions (collapsed landing gear, etc.) on passenger evacuations. The FlexSim features visual simulation, wing root sections with working flaps, and functional escape slides. Newton Design is very proud to be a part of the FAA’s ongoing mission to improve air transportation safety.

V-XTRACT

The V-XTRACT is a full-scale vehicle casualty extraction training device designed to provide high-fidelity vehicle extraction training to military personnel. The simulator replicates the widely-used High Mobility Multipurpose Wheeled Vehicle (HMMWV), and allows the instructor to present the trainee with a number of pre-programmed vehicle extraction scenarios, including an overturned vehicle.

The V-XTRACT consists of a free-rolling simulated HMMWV (or “Humvee”), towing mechanism, lift & rotate mechanism, combat stressors (smoke generation, sounds), and data collection capability. Onboard sensors indicate/record when vehicle upset and extraction efforts occur.

The V-XTRACT is used to teach trainees the procedures and techniques for extracting occupants from an overturned HMMWV. The V-XTRACT is loaded with simulated casualty dummies and is towed by a human-operated vehicle, simulating a convoy. With one button push from the remote instructor control touchpad, the instructor releases the V-XTRACT from the tow vehicle. The V-XTRACT onboard sensor and logic systems bring the V-XTRACT to a gentle stop, then command the lift/rotate system to engage, positioning the V-XTRACT in the desired state (rolled over on its side or top) for the training scenario. The trainees are then tasked with safely extracting the life-size mannequins as various challenges are presented to the, including jammed doors, simulated smoke, and scent generation.

The V-XTRACT concept can be applied to a multitude of vehicle and weapons systems, including underwater egress from aircraft cockpits/cabins. Specific features and capabilities can be modified to suit the training requirements of the individual customer.

quantified design solutions

Newton Design has utilized our capabilities to support multiple research and testing efforts, including repair of aircraft doors after a breaching event, unmanned aerial systems support, and aircraft cabin safety research. Newton Design is an active participant in the Small Business Innovation Research (SBIR) program. Through our advanced research and development partner Quantified Design Solutions, we can respond to customer's changing training needs and expand their capability to include computer-based, virtual, and augmented training systems.

Quantified Design Solutions was started as an advanced research and development partner company to integrate those capabilities into their current training portfolio. In addition to enhancing Newton's current training systems, Quantified Design was also developed to expand training system offerings into the medical domain and provide training and acquisition support services for government and commercial clients.

MIXED REALITY TACTICAL TRAINER

The M1A2 SEP V2 MRTT is a Mixed-Reality Training System used to train tank crew members using a combination of virtual reality visual simulation and physical crew member stations. The MRTT is comprised of three modular crew member stations (commander, driver, gunner), allowing the MRTT to be easily transported. The crew member stations are deployed in the training facility as the user desires. A distributed Input/Output (I/O) system links the stations together to provide integrated crew training that simulates the crew members working together in a single tank. Crew member station physical hardware included crew seats, control panels, control sticks/wheels and pedals, and gunsights.